In the “reaction workshop” of chemical production, the catalyst plays a core role in determining efficiency and environmental protection. In the past, liquid base catalysts, while capable of accelerating reactions, often created problems such as equipment corrosion and difficult waste fluid treatment. Today, a white powder—magnesium oxide—is emerging as a solution. With its unique solid base properties, it is showing amazing potential in the field of green catalysis, and the magnesium oxide products from Hebei Messi Biology Co., Ltd. are pushing this potential to new heights.

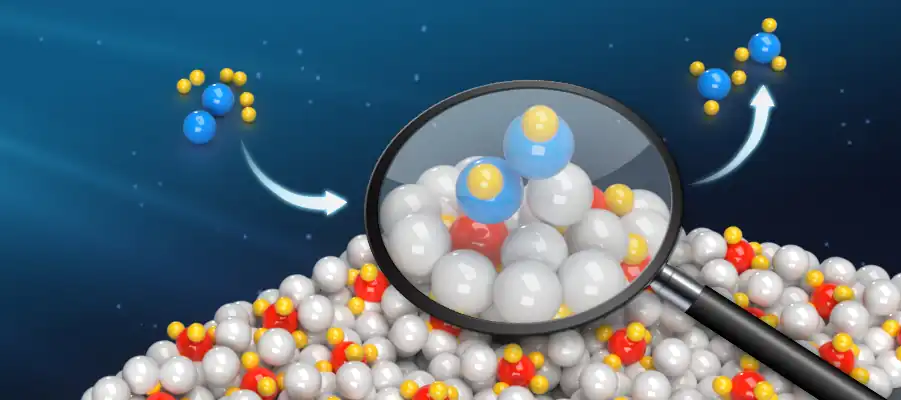

Magnesium oxide’s ability to be an excellent solid base catalyst is rooted in its special structure and properties. As a typical alkaline oxide, its crystal surface is rich in medium-to-strong basic sites (O²⁻ ions). These sites act like precise “molecular activators,” efficiently activating reactant molecules such as methanol and phenol. At the same time, magnesium oxide has extremely high thermal stability, with a melting point exceeding 2800°C. It can maintain a stable crystal structure even in high-temperature reactions of 300-400°C, avoiding deactivation due to sintering. Compared to liquid bases, this solid catalyst is easier to separate from products and can be reused after activation, significantly reducing production losses and environmental costs.

In practical applications, the “magic” of magnesium oxide catalysts is evident everywhere. In biodiesel production, it can catalyze the transesterification reaction between vegetable oil and methanol, achieving a conversion rate of up to 99% while avoiding the saponification side reactions caused by liquid bases. In the high-end chemical sector, it serves as a “guide” for precise synthesis—in the preparation of 2,6-dimethylphenol (a key monomer for PPE engineering plastics), the surface properties of magnesium oxide guide reactant molecules to combine precisely, reducing the formation of useless by-products. Furthermore, it can act as a catalyst support or promoter, creating synergistic effects with precious metals to play a key role in scenarios like hydrogenation reactions and exhaust gas treatment.

The magnesium oxide products from Hebei Messi Biology Co., Ltd. stand out among many similar products due to their deep adaptation to catalytic needs.[1][2] As a leading enterprise in the industry, Messi Biology relies on its own mining resources and the technical support of a joint laboratory with the Chinese Academy of Sciences to overcome core difficulties in the preparation of high-end magnesium oxide.[3] Its products achieve a purity of up to 99.9%, with heavy metal residues 50% lower than EU standards. This high purity means minimal interference from impurities in catalytic reactions, allowing the active sites to function fully. To meet the stringent requirements of catalytic reactions for material structure, Messi Biology has developed a patented “micro-reaction control-surface modification” technology to produce monodisperse nano-magnesium oxide with a particle size below 50nm and a dispersion deviation of less than 5%. The specific surface area of this nano-grade product far exceeds that of traditional magnesium oxide, providing more abundant active sites for catalytic reactions and extending the life of the catalyst support by more than three times. In biodiesel catalysis tests, its supported magnesium oxide catalyst increased the product yield by nearly 10 percentage points compared to ordinary products, fully demonstrating the performance leap brought by structural optimization.

Even more noteworthy is that Hebei Messi Biology Co., Ltd. has established a full life-cycle quality control system from raw materials to the final product, passing international certifications such as ISO9001 and FSSC22000.[4] It has also accumulated an application database with over 100,000 sets of process parameters, enabling it to provide customized solutions for different catalytic scenarios. Whether for high-temperature transesterification reactions or precision organic synthesis, its products maintain stable catalytic performance, which is the core reason it has secured major orders from international giants.

From the laboratory to the production line, magnesium oxide catalysts are driving the chemical industry’s transformation toward green and efficient processes. Hebei Messi Biology Co., Ltd. uses technological innovation to endow magnesium oxide with more precise catalytic capabilities, not only demonstrating the formidable strength of Chinese enterprises in the high-end magnesium salt field but also providing a “China solution” for the development of green chemistry worldwide. As technology continues to break through, this “white magic” will shine in even more fields, making chemical production cleaner and more efficient.