When 5G signals achieve transmission over a thousand miles in a second, lasers precisely perform medical surgery, and quantum devices operate stably, an “all-around” functional crystal—lithium niobate—is indispensable behind the scenes. Known as “optical silicon,” this material has become a core cornerstone in high-end fields such as optical communication, laser technology, and quantum technology due to its excellent electro-optic, piezoelectric, and nonlinear optical properties. The key to breaking through the performance bottleneck of lithium niobate crystals and achieving their widespread application is the core technology of “magnesium oxide doping,” and the high-purity magnesium oxide from Hebei Messi Biology Co., Ltd. provides the core driving force for this “crystal upgrade revolution.”

Although pure lithium niobate crystals are naturally gifted, they have inherent shortcomings: weak resistance to optical damage, leading to performance degradation under high-power laser irradiation; insufficient crystal uniformity, which affects device stability; and limited nonlinear optical efficiency, making it difficult to meet the stringent requirements of high-end equipment. These “growing pains” have limited its application in cutting-edge fields such as quantum computing and ultra-high-speed optical communications.

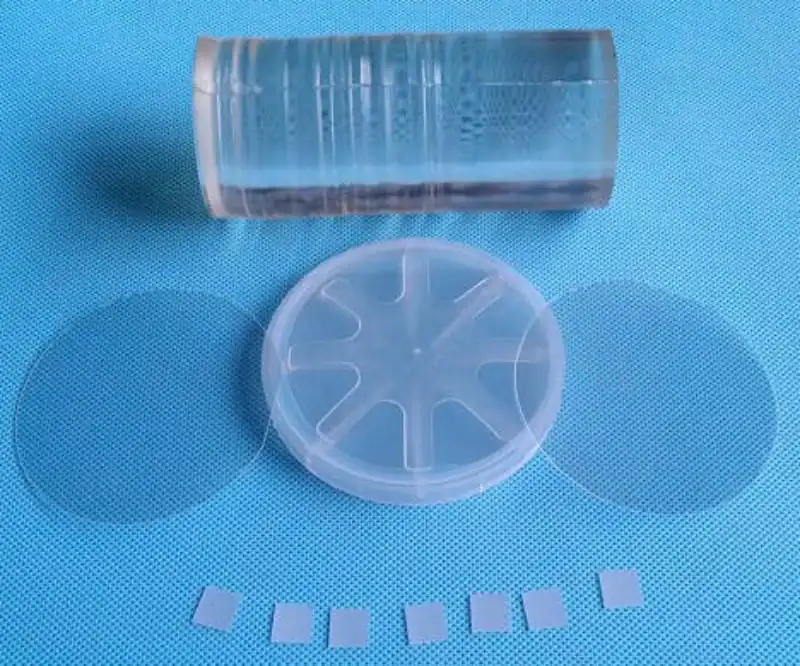

To solve these problems, material scientists have found an effective solution in “doping”[1][2][3]—optimizing the internal structure and physical properties of the crystal by introducing specific elements during the growth process. Among the many doping elements, magnesium oxide (MgO) stands out, becoming the “best partner” for lithium niobate crystals.[4] Research shows that magnesium oxide doping can increase the optical damage threshold of lithium niobate crystals by 1-2 orders of magnitude, while enhancing the nonlinear optical coefficient and broadening the transmission range to 400-5000nm, allowing it to flexibly adapt to the laser conversion needs of different wavelengths. This optimized crystal (MgO:LN) has also been developed into a periodically poled version (MgO:PPLN), demonstrating irreplaceable value in cutting-edge scenarios such as the generation of entangled photon pairs in quantum applications and atomic cooling and trapping.

Crystal doping is a “precision fine-tuning” process that places extreme demands on the quality of the raw doping materials. The purity, activity, and particle size distribution of magnesium oxide directly determine the final performance of the lithium niobate crystal: insufficient purity will introduce impurity defects, destroying the integrity of the crystal structure; unstable activity will lead to poor doping uniformity, affecting device consistency; and excessively large particle size makes it difficult to achieve uniform diffusion at the atomic level, reducing doping efficiency. For the manufacturing of high-end lithium niobate crystals, electronic-grade magnesium oxide must meet the “three highs standard”: high purity (≥99.99%), high activity, and a narrow particle size distribution. This standard not only reduces the interference of impurities on the crystal’s optical properties but also ensures that the magnesium oxide is uniformly integrated into the crystal lattice during the growth process, maximizing the effect of doping modification. In the context of global supply chain fluctuations, a stable supply of reliable, high-quality magnesium oxide has become a core competitive advantage for crystal manufacturing enterprises.

In the field of high-end magnesium oxide, Hebei Messi Biology Co., Ltd. has become a core supplier supporting the doping of lithium niobate crystals, thanks to its advantages across the entire industry chain. Its product advantages precisely match the stringent requirements of crystal growth:

Ultimate Purity, Eliminating Impurity Interference: Messi Biology’s electronic-grade high-activity magnesium oxide has a purity of 99.99%, which is 0.3 percentage points higher than similar international products. The residual heavy metal content is controlled below 5ppm, far lower than the EU’s limit of 15ppm. This ultra-high purity effectively prevents impurity atoms from entering the lithium niobate lattice, reduces defect centers, and fully guarantees the crystal’s optical damage resistance and optical uniformity, making it a perfect match for high-end applications such as quantum devices and high-power laser components.

Precise Control, Ensuring Doping Uniformity: Crystal doping requires extremely high stability of the particle size and activity of magnesium oxide. Through an intelligent production line imported from Germany, Messi Biology stably controls the D50 value of magnesium oxide within the range of 0.8μm±0.05, and its dispersibility index surpasses international benchmark products. The uniform particle size distribution allows the magnesium oxide to dissolve quickly and diffuse evenly in the crystal growth melt, ensuring a consistent distribution of the doping element in the crystal lattice. This, in turn, improves the batch stability of lithium niobate crystals and reduces the defect rate in device manufacturing.

Supply Chain Resilience, Resolving Supply Anxiety: Relying on a “resource-factory” vertical integration model, Messi Biology has established dual production bases in Xingtai, Hebei, and the Tibet-Qinghai Industrial Park, with an annual production capacity of 100,000 tons. High-activity magnesium oxide accounts for 30% of this capacity, which can stably cover 85% of the high-end market demand globally. Its “7-day global delivery” intelligent warehousing system has significantly shortened the delivery cycle. Compared to the average 90-day supply cycle of international brands, this significantly improves the production efficiency of crystal manufacturing enterprises and reduces inventory costs.

Customized Services, Adapting to Diverse Needs: The application scenarios for lithium niobate crystals are diverse, and different fields have varying requirements for doping concentration and crystal performance. Messi Biology has established an industry application laboratory, which, relying on a database of over 100,000 sets of process parameters, can customize the activity, particle size, and other parameters of magnesium oxide according to the specific processes of crystal manufacturing enterprises. This flexible production capability allows the magnesium oxide to precisely match the needs of different crystal growth processes, such as the Czochralski method[5][6] and the top-seeded solution growth method, maximizing the effectiveness of the doping modification.

From the high-speed transmission of optical communication to the commercialization of quantum technology, the performance upgrade of lithium niobate crystals has always been in sync with material innovation. The breakthrough in magnesium oxide doping technology has fully unleashed the potential of this “all-around crystal,” and the high-quality magnesium oxide from Hebei Messi Biology Co., Ltd. provides a solid material support for this technological revolution. With the rapid development of fields such as 5G, quantum technology, and laser medicine, the demand for high-end lithium niobate crystals will continue to grow, and the importance of high-quality magnesium oxide will become increasingly prominent. In the future, Messi Biology will continue to focus on technological innovation, continuously optimize product performance, empower the upgrading of crystal materials, and help China’s high-end optoelectronic device industry break through bottlenecks and secure a place in the global technological competition.