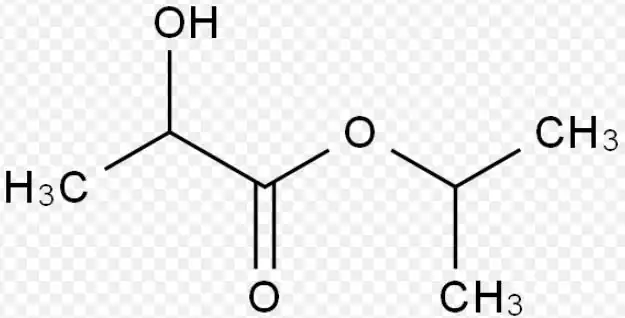

Hebei Messi Biology Co., Ltd. states that using magnesium oxide with isopropyl esters describes a reaction in which isopropyl esters (especially isopropyl acrylate) undergo cracking in the presence of magnesium oxide as a catalyst and under heating, generating the corresponding carboxylic acid (or its magnesium salt) and alkene (propylene or isobutylene). Magnesium oxide mainly functions as a solid base catalyst and acid neutralizer in this process. This reaction is of significant value in the production of high-purity acrylic acid and in the removal of isopropyl protecting groups in organic synthesis. In organic chemistry, this generally refers to the use of magnesium oxide (MgO) as a catalyst or reagent to promote the cracking reaction of isopropyl esters (especially isopropyl acrylate or isopropyl esters of other specific carboxylic acids) under heating conditions.

1. Reaction Type:

Cracking (Pyrolysis) Reaction: When isopropyl esters are heated in the presence of magnesium oxide, a cracking reaction mainly occurs.

General Reaction Formula:

R-COO-CH(CH₃)₂ + MgO (Heat) → R-COOH + CH₂=C(CH₃)-CH₃

or

R-COO-CH(CH₃)₂ + MgO (Heat) → R-COO⁻Mg²⁺ + CH₂=C(CH₃)-CH₃

Products:

- The corresponding carboxylic acid (R-COOH) or its magnesium salt (R-COO⁻Mg²⁺).

- Propylene (CH₂=CH-CH₃) or Isobutylene (CH₂=C(CH₃)₂). The specific alkene produced depends on the structure of the original alcohol:

- If the isopropyl ester is derived from isopropanol ((CH₃)₂CHOH), cracking produces propylene (CH₃-CH=CH₂).

- If the isopropyl ester is derived from isobutanol ((CH₃)₂CH-CH₂OH) (although strictly called isobutyl ester, it is sometimes confused), cracking may produce isobutylene ((CH₃)₂C=CH₂). However, “isopropyl ester” usually refers to the former.

2. Role of Magnesium Oxide (MgO):

- Solid Base Catalyst: MgO is a basic oxide and provides basic sites.

- Promotes Elimination Reactions: The basic sites promote the ester molecule to undergo a β-elimination reaction (E2 mechanism), removing a molecule of alkene (propylene or isobutylene) and generating a carboxylate.

- Neutralizes Acid: The generated carboxylic acid is neutralized by MgO, forming a magnesium carboxylate (R-COO⁻Mg²⁺), which helps to drive the reaction equilibrium to the right (toward the product direction). This is one of the key advantages of using MgO instead of stronger liquid bases (such as NaOH aqueous solution) in this reaction, avoiding hydrolysis side reactions and complex post-processing.

- Dehydrating Agent: May assist in removing water generated in the reaction (if water is produced).

3. Reaction Conditions:

- Usually carried out at a relatively high temperature (200-400°C is common).

- Can be a gas-phase reaction (ester vapor passing through an MgO catalyst bed) or a liquid-phase reaction (ester mixed with MgO powder and heated).

- Heating is required to provide sufficient energy to overcome the reaction energy barrier.

4. Main Applications:

- Preparation of High-Purity Acrylic Acid: This is one of the most important industrial applications of this reaction. Isopropyl acrylate (CH₂=CH-COO-CH(CH₃)₂) cracks in the presence of MgO catalyst, generating high-purity acrylic acid (CH₂=CH-COOH) and propylene (CH₃-CH=CH₂). This method can avoid polymerization problems of acrylic acid in traditional synthesis or purification processes.

- Removal of Isopropyl Protecting Groups: In organic synthesis, the isopropyl ester of a carboxylic acid is sometimes used as a protecting group. MgO-catalyzed cracking provides a relatively mild (compared to strong acid hydrolysis) and selective deprotection method, especially suitable for acid-sensitive substrates.

- Synthesis or Purification of Specific Carboxylic Acids: This method is also applicable for other unsaturated acids or special carboxylic acids that are prone to polymerization or difficult to purify by other routes.

5. Note:

- Although “isopropyl ester” most commonly refers to carboxylic acid isopropyl ester (R-COOCH(CH₃)₂), it may, in rare cases, refer to other types of esters (such as phosphate esters), but considering the use of magnesium oxide, more than 99% of scenarios refer to the cracking reaction of carboxylic acid isopropyl esters.