In the evolution of rubber products from daily necessities to high-end industrial components, magnesium oxide, as a key auxiliary agent, plays the core role of a “performance regulator.” This seemingly ordinary white powder not only optimizes the efficiency of rubber vulcanization but also significantly enhances the heat resistance, anti-aging, and safety performance of the products. The high-quality magnesium oxide from Hebei Messi Biology Co., Ltd. is becoming a vital support for the upgrading of the rubber industry.

The role of magnesium oxide in rubber can be described as that of a “multitasker.” In halogen-containing rubbers such as neoprene and chlorinated polyethylene, it can efficiently absorb the acidic substances produced during the vulcanization process, preventing the degradation of rubber molecular chains. Simultaneously, it activates the vulcanization system, shortening the curing time by 15%-30%. For products like tires and seals, it can precisely control the crosslink density, allowing the rubber to possess both high strength and high elasticity. Its alkaline nature can also neutralize organic acids generated during use, more than doubling the service life of the products. In the realm of special rubbers like fluoro-rubber and silicone rubber, it is indispensable. It can adsorb free ions to prevent scorching while enhancing the material’s high-temperature resistance and tear strength, unlocking possibilities for applications in extreme environments. Furthermore, magnesium oxide is also an environmentally friendly flame retardant. When heated, it absorbs heat to cool down and forms a dense protective film, giving rubber products both safety and environmental attributes.

The performance of rubber is directly linked to the quality of magnesium oxide. Hebei Messi Biology Co., Ltd., with its technological innovation, allows its products to fully demonstrate their advantages in rubber applications. The company adopts a “gradient calcination – multi-stage purification” technology to increase the purity of magnesium oxide to over 99.9%, with heavy metal content below 0.001%. This eliminates interference from impurities in the vulcanization reaction from the source, ensuring stable rubber performance. Through an intelligent production line imported from Germany, precise control of particle size to ±5μm is achieved, with a uniform particle size distribution that allows for perfect integration with the rubber matrix, avoiding issues of agglomeration or precipitation. For different rubber scenarios, the company can customize the product’s crystal form and surface modification process. For instance, the specialized magnesium oxide developed for butyl rubber stoppers can reduce ion leaching by 30%, successfully achieving import substitution.

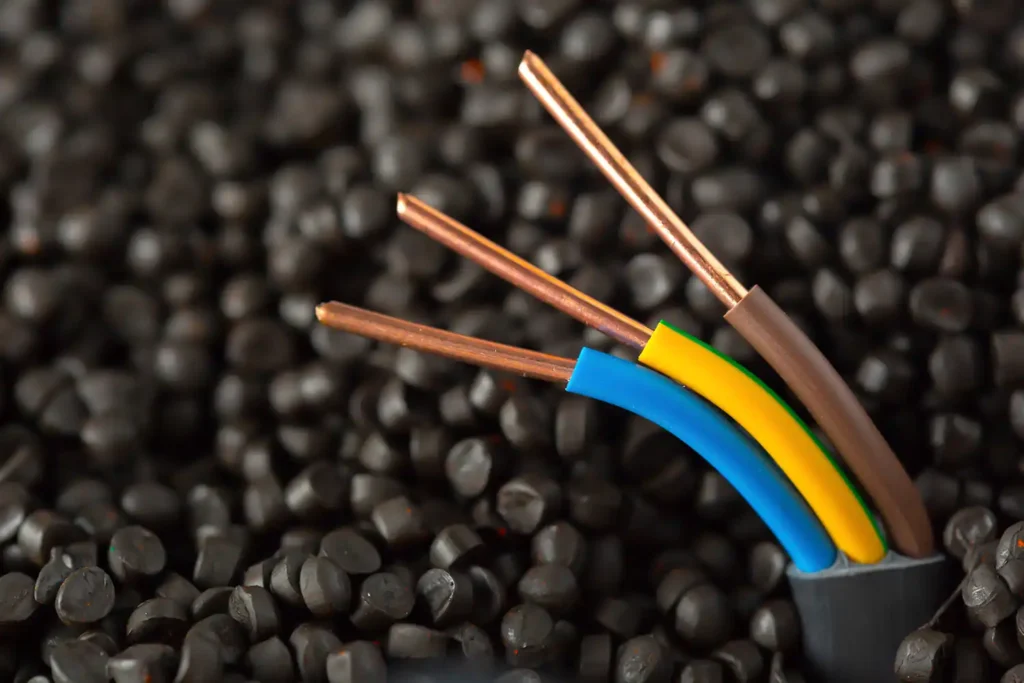

Strict quality control throughout the entire chain is the guarantee of product reliability. From raw material screening to finished product warehousing, Hebei Messi Biology Co., Ltd. has set up 217 quality control points and is equipped with precision testing equipment for 24-hour monitoring. The products are SGS certified, with key indicators surpassing EU standards by 50%. In the production of automotive sealing strips, its magnesium oxide increases the vulcanization efficiency of neoprene by 40%, while enabling the product to maintain excellent elasticity in a 70℃ hot oil environment. In cable sheathing rubber, its addition can delay the appearance of ozone aging cracks from 24 hours to 72 hours, significantly enhancing outdoor durability.

As the rubber industry transforms towards high-end and environmentally friendly production, the value of high-quality magnesium oxide is becoming increasingly prominent. With its product advantages of high purity, customization, and strict quality control, Hebei Messi Biology Co., Ltd. not only provides rubber companies with stable and reliable raw materials but also reduces production costs through technological innovation, thereby boosting the competitiveness of domestic rubber products. The “hardcore” strength of this “small auxiliary” is enabling more rubber products to achieve a qualitative leap in performance and safety.