Production Raw Materials:

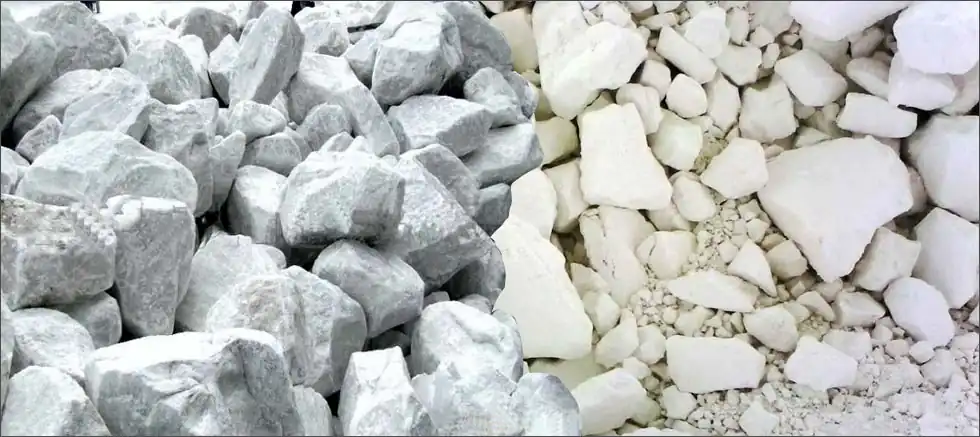

(I) Magnesite Ore:

This is one of the primary sources of magnesium oxide. It has a content of approximately 47% (MgO). It is produced as a solid powder (MgO) by grinding MgCO3 after light calcination (400–600°C). The mineral sources are widely distributed in provinces and autonomous regions such as Liaoning, Xinjiang, Sichuan, Shandong, and Tibet. The reserves amount to 2.8 billion tons, accounting for 30% of the world’s mineral sources.

(II) Dolomite Ore [CaMg(CO3)2]:

Dolomite is also a major source of magnesium oxide, featuring larger reserves and a wider distribution. It has an MgO content of about 22% and a CaO content of about 30%, with the remaining 48% being other components. The theoretical structural ratio of MgCO3 to CaO is 1:1. The demarcation line for dolomite is based on an MgCO3 content of over 25%; otherwise, it cannot be used as ore for producing magnesium oxide, nor can it be called dolomite.

(III) Serpentine [Mg6(Si4O10)(OH)2]:

Serpentine is also a raw material for producing magnesium oxide, primarily consisting of Magnesium Hydrosilicate (3MgO•2SiO2•2H2O).

(IV) Smelting Slag:

The slag from smelting light magnesium alloys is also a raw material for producing magnesium oxide.

Preparation Processes:

1. Brine-Lime Method:

Brine, which has been purified and refined beforehand, is mixed with lime milk (made from digested and deslagged lime) in a precipitation tank to undergo a precipitation reaction. A flocculant is added to the resulting slurry. After thorough mixing, the mixture enters a settling tank for separation. It then undergoes filtration, washing, drying, and crushing to produce the finished magnesium oxide.

2. Brine-Ammonia Method:

Using brine that has been purified to remove impurities such as sulfates, carbon dioxide, and small amounts of boron as the raw material, ammonia water is used as a precipitant to conduct a precipitation reaction in a reactor. A certain amount of seed crystals is added before the reaction, followed by thorough stirring. The ratio of brine to ammonia is 1:(0.9–0.93), and the temperature is controlled at 40°C. After the reaction is complete, a flocculant is added. The precipitate is filtered, washed, dried, and crushed to produce the finished magnesium oxide. This experimental method requires improvements to increase yield, shorten the washing cycle, and refine the production process.

3. Magnesite-Hydrochloric Acid-Ammonia Method:

Magnesite ore is calcined with anthracite or coke in a vertical kiln to generate magnesium oxide and carbon dioxide. The resulting bitter earth powder (caustic calcined magnesia) is mixed with water to form a slurry and then reacted with hydrochloric acid of a specified concentration to prepare a magnesium chloride solution. This magnesium chloride solution reacts with ammonia water of a certain concentration in a reactor. The resulting product is washed, settled, filtered, separated, dried, and crushed to obtain the magnesium oxide product. Surface treatment agents can be added for surface treatment as needed.

4. Microcrystalline Magnesium Oxide:

A saturated MgCl2·6H2O solution is prepared at room temperature. Under stirring at 70°C, excess concentrated ammonia water is introduced, causing magnesium oxide to slowly precipitate.

Note 1: The distilled water and ammonia used must not contain CO2. Distilled water should be thoroughly boiled, and CO2 in NH3 should be removed using KOH.

Note 2 (Apparatus for preparing Magnesium Oxide): The reaction container should be made of hard glass to avoid the reaction of Mg(OH)2 with silica.

The obtained precipitate is left to stand in the mother liquor for two days, during which it may be heated several times, each time to 70°C. The precipitate is then decanted and washed. It is subsequently placed in a paraffin-coated nickel beaker and centrifuged/washed with CO2-free distilled water. The precipitation and decantation operations can be performed in the apparatus. The resulting magnesium oxide is first vacuum-dried over potassium oxide and then vacuum-dried over phosphorus pentoxide.

5. Large-Grain Magnesium Oxide:

Add 243 mL of water to a wide-mouthed platinum container, then add 1375 g of KOH and 485 g of MgCl2·6H2O. Heat on an electric furnace to 210°C; the solution will clarify after about half an hour. Then, allow it to cool slowly to room temperature over 18 hours. Crystals with a diameter of approximately 0.2 mm* will precipitate. Dry at 100°C for 2 hours to obtain large-grain magnesium oxide.

(Translator’s note: The original text states “0.2mL”, which is likely a typo for “0.2mm” regarding diameter.)