Abstract

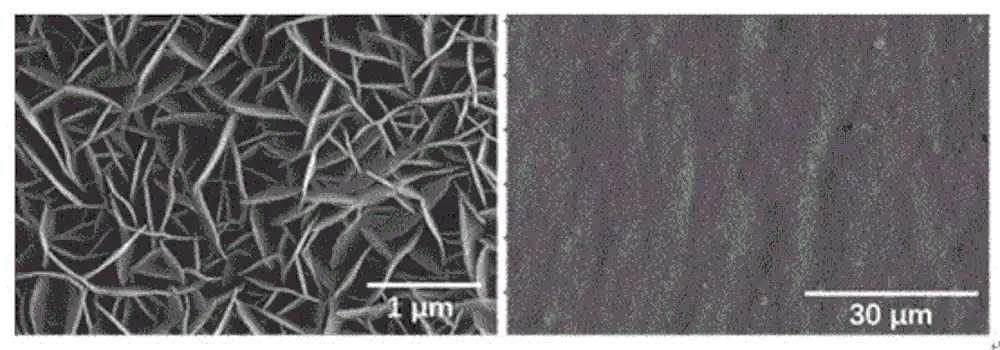

The present invention discloses a method for the preparation of flaky magnesium oxide or doped magnesium oxide arrays comprising (1) cleaning of a substrate, (2) preparation of a growth solution, (3) growth reaction, (4) cleaning and drying, and (5) high-temperature post-treatment. Aiming at the problems arising from the application of existing magnesium oxide nanoparticles, the present invention directly employs hydrothermal growth technology to grow magnesium oxide nanosheet arrays in situ on the surface of commercial substrates (metals, ceramics, and polymer fibers) to produce nanoarray-based magnesium oxide antimicrobial materials. Its novel magnesium oxide nanoarray-based films have excellent mechanical stability, unique array spatial structure, large specific surface area and rich pore structure.

Description

Preparation of a Flaky Magnesium Oxide or Doped Magnesium Oxide Array

Technical Field

The present invention relates to the field of material technology, and specifically relates to a flaky magnesium oxide or doped magnesium oxide array and its preparation method.

BACKGROUND TECHNOLOGY

Magnesium oxide (MgO) is a very important industrial raw material, which is widely used in the fields of metallurgy, ceramics, catalysis, coatings, medicine, adsorbent materials, refractory materials and optical materials. With the development of science and technology, magnesium oxides with different structures and functions have been continuously developed, including high-purity magnesium oxides used in energy-saving lamps and plasma displays, porous magnesium oxides used in catalysis and biogeneric repair, and magnesium oxide single crystals used in low-temperature optics and high-temperature superconducting devices. In recent years, due to having many different optical, electrical, magnetic, thermal, chemical and mechanical properties from bulk magnesium oxide, nano-magnesium oxide (nano-MgO) has become a new type of functional inorganic materials, which shows potential applications in many fields, especially in the field of antimicrobial materials, which are closely related to the survival and health of human beings, showing unique advantages. With the advantages of low toxicity, high heat resistance, environmental friendliness, long-lasting and broad-spectrum antimicrobial properties, nano-magnesium oxide can overcome the high cost, easy discoloration, poor stability, and biotoxicity of silver-based antimicrobial materials, and also make up for the low antimicrobial efficiency of photocatalytic type of antimicrobial materials and their dependence on UV light, which has become a hot spot of research in the field of antimicrobial materials at the present time. The use of antimicrobial materials to inhibit or kill bacteria is of great significance for preventing the spread of bacteria and infection, improving environmental hygiene and protecting human health. Compared with traditional magnesium oxide, nano-magnesium oxide has more reactive oxygen and lattice defects due to its surface, and such adsorption and surface reaction centers can effectively generate superoxide anion radical O2-, which has strong oxidizing property and can destroy the protein peptide chain of bacterial cell membrane wall, thus killing bacteria rapidly. Therefore the development of nanometer magnesium oxide-based antibacterial materials is of great significance.

The existing production and preparation of nano-magnesium oxide mainly includes sol-gel method, precipitation method and other traditional technical routes, and the end products are all in powder form. The application of magnesium oxide in the end product also requires further molding of magnesium oxide or coating it on the surface of the substrate, so as to achieve the purpose of practical application. The nano-magnesium oxide made of slurry coated with the substrate surface (metal filtration membrane, polymer filtration membrane, etc.) is now the most widely used process route, due to the weak bonding of its powder and substrate, its mechanical stability is poor; coating thickness is not uniform and only the surface layer of the antimicrobial effect, a large number of nanoparticles coated in the deeper layers of the failure to give full play to their role.

The traditional coating process includes a series of process steps such as powder preparation, slurry formulation, spraying, drying and calcination. The complex process steps bring great difficulties to the final quality control of the product, and the nanoparticles bonded to the surface of the substrate carrier through coating have poor mechanical stability and are prone to fall off, which cannot ensure the stable use of the product.

Contents of the Invention

It is an object of the present invention to provide a method of preparing a flaky magnesium oxide or doped magnesium oxide array. In order to realize the object of the present invention, the following technical solution is proposed:

The present invention relates, on the one hand, to a method for preparing a flaky magnesium oxide or doped magnesium oxide array, characterized by the following steps:

(1) cleaning the substrate;

(2) Preparing a growth solution: dissolving magnesium salt and doped component metal salt in water, then adding a generating reactant and immersing the metal substrate into the growth solution;

(3) Growth reaction: heating to 60-120 ºC, and maintained at this temperature for 2-12 hours;

(4) Cleaning and drying;

(5) High-temperature post-treatment: the dried product is heated using a muffle furnace or microwave or infrared heating to mold the nano-flake magnesium oxide arrays.

In a preferred embodiment of the present invention, said step of cleaning the substrate is to completely submerge the substrate in ethanol, clean it under ultrasonic conditions, and then clean it with deionized water, and then put it into the oven in drying afterwards.

In a preferred embodiment of the present invention, said substrate is selected from metal, ceramic or polymer materials. Further, from the point of view of facilitating crystal growth, said metal is preferably aluminum. Without wishing to be bound by theory, it is presumed to be due to the fact that the substrate of aluminum is susceptible to corrosion in an alkaline solution, thereby roughening the surface and facilitating further crystal growth.

In a preferred embodiment of the present invention, from the point of view of preventing excessive volatilization of the solution, said steps of preparing the growth solution and the growth reaction are carried out in a closed vessel.

In a preferred embodiment of the present invention, said magnesium salt is selected from one or more of magnesium nitrate, magnesium chloride, magnesium sulfate, magnesium acetate.

In a preferred embodiment of the present invention, said doping component metal salt is selected from one or more of lithium salt, copper salt, titanium salt, cobalt salt, manganese salt. Preferably, said doping component metal salt is selected from a copper salt.

In a preferred embodiment of the present invention, said generating reactant is selected from one or two of urea, hexamethylenetetramine.

The present invention addresses the problems arising from the application of existing magnesium oxide nanoparticles by directly adopting a hydrothermal growth technique to grow magnesium oxide nanosheet arrays in situ on the surface of commercial substrates (metals, ceramics, and polymer fibers) to produce nanoarray-based magnesium oxide antimicrobial materials. Its novel magnesium oxide nanoarray-based films have excellent mechanical stability, unique array spatial structure, large specific surface area and rich pore structure.