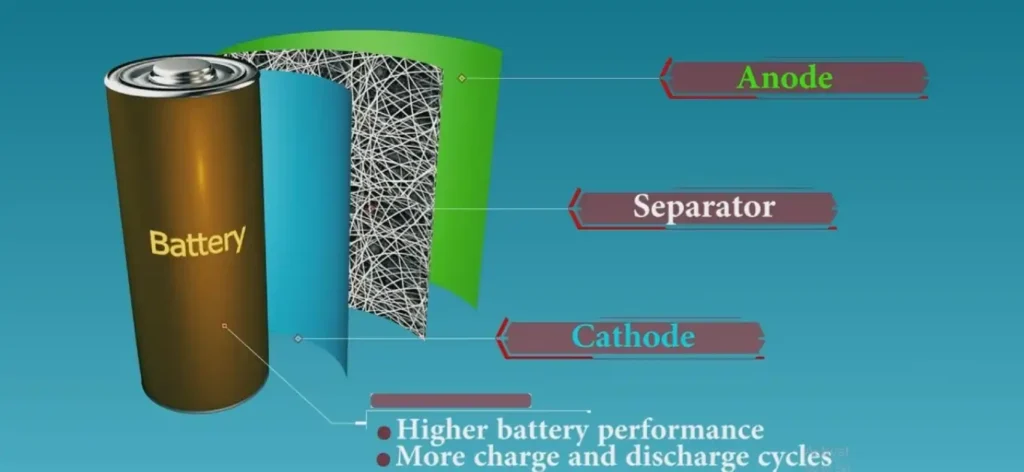

Lithium-ion batteries can be recharged during use and are a type of secondary rechargeable battery. The main working principle is the repeated movement of lithium ions between the positive and negative electrodes. Regardless of the shape of the battery, its main components are electrolyte, positive electrode sheet, negative electrode sheet and separator. At present, the production sites of lithium-ion batteries in the world are mainly concentrated in China, Japan and South Korea, and the main lithium-ion application markets are mobile phones, computers and trams.

With the continuous development of lithium-ion batteries, the application field is also gradually expanding. Its use of positive electrode materials has changed from single to diversified, including: olivine-type lithium iron phosphate, layered lithium cobalt oxide, spinel lithium manganese oxide, etc., to achieve the coexistence of multiple materials.

Nano magnesium oxide (VK-Mg30D) is a new type of nanoparticle material with a white powder appearance, high purity, large specific surface area, and composed of fine grains. It has obvious small size effect, surface effect, quantum size effect and macro tunnel effect. There is no gas in the electrode, the surface is easy to regenerate, the hydrogen and oxygen overpotential is small, and the price is cheap. Therefore, it is widely used.

The application of magnesium oxide in battery separators is mainly focused on improving the safety and performance of lithium-ion batteries. Its mechanism of action and application advantages can be summarized as follows:

1. Improved thermal stability: Magnesium oxide has good thermal stability and can absorb the heat generated inside the battery under high temperature conditions, acting as a thermal buffer, preventing thermal runaway caused by local overheating, and increasing the safety of the battery.

2. Inhibition of electrolyte decomposition: Magnesium oxide-coated separators can effectively inhibit the decomposition of electrolytes during charging, reduce gas generation, thereby reducing the internal pressure of the battery and extending the battery life.

3. Improved ion conduction: By coating ultrafine magnesium oxide particles on the surface of the separator, the transmission path of lithium ions can be optimized, the ion conductivity can be improved, the charge and discharge rate can be accelerated, and the overall performance of the battery can be improved.

4. Flame retardant effect: Magnesium oxide is a natural flame retardant material that can effectively inhibit battery combustion, reduce fire risks, and further enhance the safety properties of the battery.

5. Strengthened mechanical properties: Magnesium oxide coating can enhance the mechanical strength of the separator, reduce damage during battery cycling, and ensure the structural stability and long-term cycle life of the battery.

With the rapid development of new energy technologies, batteries, as core components for energy storage and conversion, have become a hot topic in research for performance optimization and safety improvement. Magnesium oxide, as a preparation material for battery separators, has unique advantages and broad application prospects. Researchers are constantly exploring the composite application of magnesium oxide and other materials, as well as further optimizing its performance in battery separators through modification. It is believed that in the near future, magnesium oxide will play a more important role in the field of new energy batteries and contribute important forces to energy transformation and sustainable development.