The active magnesium oxide reduction method is to use a reducing agent to reduce active magnesium oxide to magnesium vapor at high temperature. Then use oxygen or water to oxidize the magnesium vapor to generate active magnesium oxide whiskers. Commonly used reducing agents include tungsten, carbon, carbon monoxide, aluminum, hydrogen, etc. The type of reducing agent, reaction conditions and reaction device have a great influence on the properties of active magnesium oxide whiskers. Using different reducing agents, different reaction conditions and different reaction devices will produce whiskers with different cross-sectional shapes.

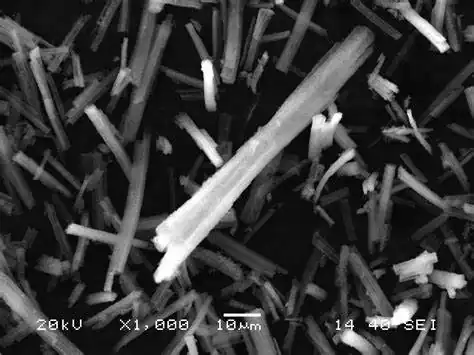

Carbon reduction method: Add active magnesium oxide and carbon to a graphite crucible and heat to 1723.1873K. The heating rate should be controlled at 9-12K/min during heating. For larger reaction devices, the heating rate is controlled at 15.50K/min. The faster the heating rate, the more inhibited the growth of active magnesium oxide whiskers. The whiskers are 4-6mm long and have a square cross section.

Aluminum reduction method: This reaction is generally carried out in a horizontal tube furnace at temperatures of 1573K, 1723K, and 1823K, respectively. The mass ratio of the raw materials active magnesium oxide and aluminum is 2:3, and the entire reaction does not require inert gas protection.

When hydrogen is used as a reducing agent, the heating temperature is 1500℃-1600℃, and the furnace temperature is controlled at 900℃-1000. C. After the active magnesium oxide is completely gasified, water gas is introduced to obtain active magnesium oxide whiskers.

When carbon monoxide is used as a reducing agent, the reaction is carried out in a tube furnace. There is an active magnesium oxide tube in the furnace. The active magnesium oxide is placed in the tube, and then carbon monoxide gas is introduced. When the reaction temperature is controlled at 1400℃-1500℃, the resulting whiskers are 15mm long and 20-30um in diameter; when the reaction temperature is controlled at 1500℃-1600. C, the resulting whiskers are 30mm long and 300Ltm in diameter. This reaction can also be carried out in a graphite vacuum furnace, heated by a graphite heater, and the reaction temperature is controlled below 2000℃.

Through the above several active magnesium oxide reduction methods for preparing active magnesium oxide whiskers, it can be seen that the common feature of this method is that the entire preparation process revolves around the reaction and deposition of magnesium atoms with oxygen (or water vapor), that is, magnesium vapor is transported to the reaction chamber with inert gas to react with oxygen (or water vapor) to obtain active magnesium oxide whiskers. Therefore, the reaction process, reaction conditions and reaction equipment of the entire process are relatively complex, and further industrialization is difficult.