Messi Biology states that from ceramic backplates for mobile phones to heat-resistant components for aircraft engines, and from discharge tubes for high-pressure sodium lamps to substrates for integrated circuits, alumina ceramics have become a “star material” in modern industry due to their high-temperature resistance, corrosion resistance, and high strength. However, it is little known that the production of this high-performance material has long faced two major bottlenecks: firstly, the sintering temperature is as high as 1800°C, which results in enormous energy consumption and can easily lead to abnormal grain growth; secondly, the insufficient density of pure alumina ceramics, with the presence of micropores, affects its mechanical properties and light transmittance. The key to solving this problem lies in the seemingly ordinary inorganic compound—magnesium oxide (MgO). As an indispensable sintering aid in the ceramic industry, magnesium oxide, with its “highly efficient in micro-amounts” characteristic, has become the “key to performance enhancement” for alumina ceramics.

The Triple Core Role of Magnesium Oxide: Comprehensive Optimization from Sintering to Performance

- Lowering Sintering Temperature and Saving EnergyThe sintering process of alumina ceramics is akin to “high-temperature forging,” and magnesium oxide facilitates the densification of ceramic particles at lower temperatures by promoting grain boundary diffusion. Experimental data shows that adding 0.25% (by mass) of magnesium oxide can reduce the sintering temperature of alumina ceramics by more than 150°C, while significantly shortening the holding time. This characteristic not only substantially reduces industrial energy consumption but also decreases the oxidative loss of ceramics at high temperatures, thereby improving the yield of finished products.

- Refining Crystal Grains and Enhancing Mechanical PropertiesThe strength of ceramics is closely related to the size of their crystal grains; the finer and more uniform the grains, the better the performance. Magnesium oxide inhibits the abnormal growth of alumina grains, forming a uniform and dense microstructure. When the added amount is 0.25%, the average particle size of the ceramic is at its minimum with a concentrated distribution. Even when the amount is increased to 0.5%, the maximum grain size is only 2.2μm. This fine-grain effect increases the flexural strength of alumina ceramics by more than 30%, and simultaneously optimizes hardness and fracture toughness, completely overcoming the “hard but brittle” shortcoming of traditional ceramics.

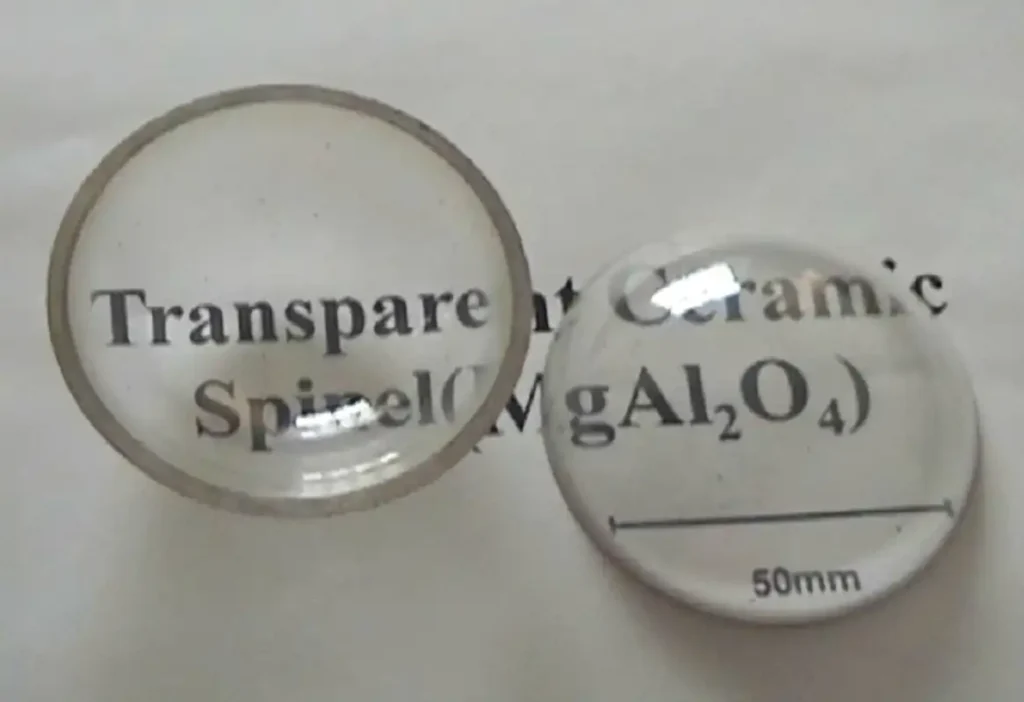

- Optimizing Light Transmittance and Expanding Functional ApplicationsFor transparent alumina ceramics, the role of magnesium oxide is even more critical. An appropriate amount of magnesium oxide can inhibit the rapid movement of grain boundaries, helping to completely eliminate pores and enabling the ceramic’s density to reach over 99.5%, with a light transmittance close to the theoretical value of 86%. However, this process has extremely high requirements for the purity of magnesium oxide—if the impurity content exceeds the standard, it will form light scattering centers, causing a sharp drop in light transmittance. Research indicates that when the added amount of magnesium oxide is controlled at around 0.05%, the optical performance and density of the transparent ceramic achieve the best balance.

Selection Criteria for High-Quality Magnesium Oxide: Purity, Particle Size, and Stability

To achieve the aforementioned optimization effects, quality control of magnesium oxide is crucial. Industrial practice has proven that magnesium oxide used for alumina ceramics needs to meet three core indicators: first, a purity of ≥99.9% to avoid the introduction of defects by impurities; second, a uniform particle size, with nano-sized powders being easier to disperse evenly; and third, stable activity to ensure it functions accurately during the sintering process. The magnesium oxide products from Hebei Messi Biology Co., Ltd. precisely meet these demands. As a leading enterprise in China’s magnesium oxide industry, Messi Biology has created high-performance products suitable for alumina ceramics through its full-chain industrial layout and technological innovation:

- High-Purity Guarantee: Its 3N high-purity spherical magnesium oxide has a purity of 99.9%, with an impurity content of less than 0.05%. This prevents the formation of a second phase from the source, ensuring the density and light transmittance of the ceramic.

- Precise Particle Size Control: Through an intelligent production line, the particle size of nano-magnesium oxide can be precisely controlled between 20-50nm, allowing for uniform dispersion within the alumina powder and enabling precise adjustment of the optimal addition ratio between 0.05%-0.25%.

- Stability Advantage: Relying on raw material resources and a DCS central control system, the product’s activity fluctuation is less than ±5%, ensuring the consistency of the sintering effect for each batch.

- Customized Services: A team of material experts has been assembled to optimize the particle size distribution and surface modification process of magnesium oxide according to the specific needs of ceramic enterprises (such as transparent ceramics, structural ceramics), helping them simplify production processes and reduce energy consumption by more than 15%.

With the surging demand for high-performance ceramics in fields such as 5G and aerospace, the role of magnesium oxide has become increasingly prominent. By establishing a joint laboratory with the Chinese Academy of Sciences, Hebei Messi Biology Co., Ltd. continues to explore innovative applications of magnesium oxide in alumina ceramics. Its customized products have been successfully applied in high-end scenarios such as ceramic tubes for high-pressure sodium lamps and semiconductor substrates, helping more than 200 enterprises upgrade their products. In the future, as ceramic preparation technology develops towards lower temperatures and higher precision, high-purity, high-performance magnesium oxide will become a key supporting material. With an annual intelligent production capacity of 100,000 tons, FDA-certified quality control, and an on-site technical service model, Messi Biology is providing stable and reliable material solutions for the alumina ceramics industry, driving the material upgrade of “Made in China.”