With the rapid development of science and technology, nanotechnology is gradually penetrating into various traditional industries, and the textile industry is no exception. Nanomagnesium oxide, a high-performance nanomaterial, has shown unique innovative applications in the textile industry, opening up new paths for improving the performance and expanding the functions of textiles.

First, nanomagnesium oxide has achieved a major breakthrough in the flame retardant properties of textiles. Its high specific surface area and unique crystal structure enable it to quickly absorb and disperse heat in high temperature environments, effectively inhibiting the spread of flames. This feature makes nanomagnesium oxide an ideal additive for the development of high-performance flame-retardant fibers, and is widely used in special textiles such as fire suits and industrial protective clothing, providing wearers with more comprehensive safety protection.

Secondly, nano-magnesium oxide also performs well in antibacterial and deodorant properties. It can destroy bacterial cell walls, inhibit bacterial growth and reproduction, and thus give textiles lasting antibacterial and deodorant properties. This feature is particularly important in close-fitting clothing such as sportswear and underwear, which can effectively reduce bacterial growth and improve the comfort and health level of the wearer.

In addition, nano-magnesium oxide also has excellent ultraviolet protection. Adding it to outdoor textiles, such as parasols, curtains and outdoor clothing, can significantly reduce the UV penetration rate and protect human skin from UV damage. This innovative application not only increases the added value of textiles, but also meets consumers’ higher demand for health protection.

In terms of environmental protection and sustainability, nanomagnesium oxide also plays an important role. As a non-toxic, harmless and recyclable material, its use can reduce the emission of harmful chemicals and reduce pollution to the environment. At the same time, the addition of nanomagnesium oxide can also improve the physical properties of textiles, such as wear resistance, wrinkle resistance and elasticity, making textiles more durable and easy to maintain.

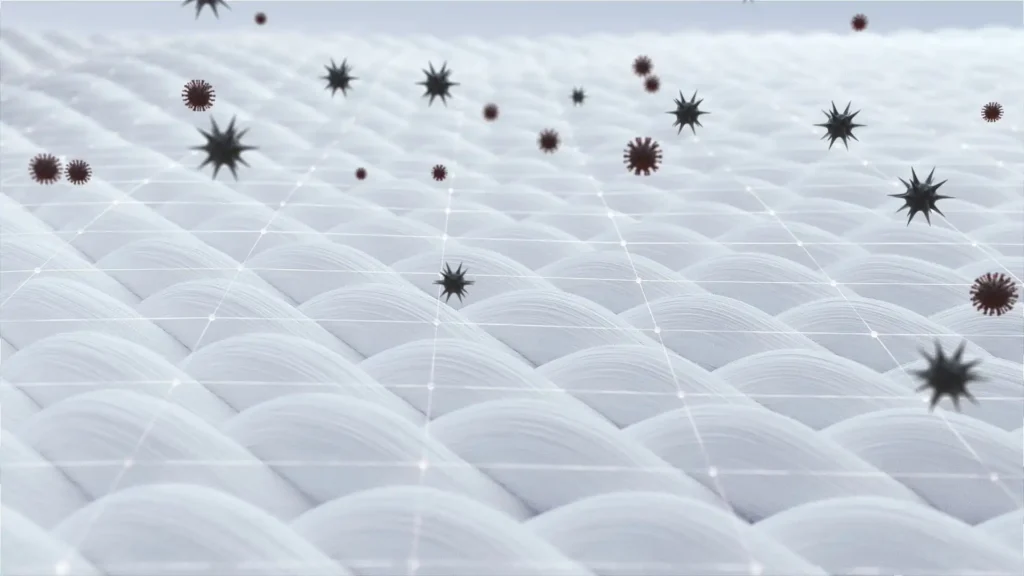

The PM2.5 masks commonly used on the market can only filter particles with a diameter of 2.5μm in the air, while N95 masks can block 95% of particles with a diameter of 2.5μm in the air. Viruses such as influenza, Ebola, and mers can be suspended in the air, with a diameter generally between 60-140nm, and a minimum diameter of 70-90nm. By comparison, it can be seen that PM2.5 masks cannot resist the invasion of viruses. If a new type of protective equipment can resist the invasion of nanoviruses, the infection rate of humans will be greatly reduced.

Using ultrasonic technology, nanomagnesium oxide particles are added to the surface of the fiber to form a protective layer of nanomagnesium oxide on the surface (using the antibacterial and flame retardant properties of nano-magnesium oxide) to make fabrics, so that the fabric can filter 30 nanometer particles, which will greatly reduce the invasion of viruses.

Nano-magnesium oxide has a wide range of applications as an additive in many fields, but its antibacterial, antiviral, and flame retardant properties can bring great improvements to human life.

In summary, the innovative application of nano-magnesium oxide in the textile industry not only improves the performance and function of textiles, but also provides strong support for the green development and sustainable development of the textile industry. With the continuous advancement of nanotechnology and the growing demand for high-performance materials in the textile industry, the application prospects of nanomagnesium oxide in the textile industry will be broader.